UPP® SEMI-RIGID PIPEWORK SYSTEM

- Home

- products

- Franklin Fueling Systems

- UPP® SEMI-RIGID PIPEWORK SYSTEM

UPP® SEMI-RIGID PIPEWORK SYSTEM

Electrofusion Pipework

UPP® pipework utilizes the advanced electrofusion welding process to effectively bond system components including pipework and containment together into one, watertight system.

UL UPP® pipe is offered in 1½”, 2″, 3″, and 4″ diameters and a variety of stick and coil sizes.

EN UPP® pipe is offered in 32mm, 50mm, 63mm, 90mm, 110mm, and 160mm diameters and a variety of stick and coil sizes.

A WATERTIGHT PIPEWORK SYSTEM SOLUTION

With over 30 years of proven performance, UPP® of semi-rigid pipework is the world’s first electrofusion pipework system for fuel applications, and remains today, the best-in-class watertight solution for pipework and containment globally.

A Watertight System

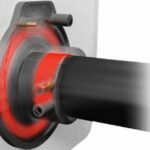

At the heart of the UPP® pipework system is the highly efficient electrofusion welding process that connects pipe, fittings, seals and containment to create a seamless, watertight direct burial pipework system.

A Versatile Pipework Solution

UPP® pipe is suitable for all UL and EN fueling applications including: product lines, vent lines, vapor lines, and above and below grade environments. The semi-rigid pipework is rigid enough to be used in place of fiberglass pipe for vapor or vent lines, yet flexible enough to coil and accommodate the bends of for product lines.

Simple, Safe, & Effective Installation

With the advanced electrofusion welder and welding process, a single button push will effectively bond system components together into one leak-proof system regardless of pipe diameter, component, or ambient temperature.

TECHNICAL ADVANTAGES

ELECTROFUSION WELDING INSTALLATION

UPP® semi-rigid pipework utilizes the advanced electrofusion welder and welding process to effectively bond system components together into one, leak-proof system.

| Fast Welding ProcessAfter connecting a welder and its leads to a fitting, the installer presses a single button to initiate the welding process. |

| A Smart WelderThe welder calculates the exact settings needed regardless of pipe diameter, component, or ambient temperature. |

| Easy for the InstallerThere is nothing for the installer to input, no language barrier to overcome, with the same process for all types of pipes, fittings, and entry boots. |

WATERTIGHT CONTAINMENT ENTRY

In both of the polyethylene and fiberglass sump sealing processes, the boot, sump, and pipework become one solid structure, creating a watertight system.

| Remove Leak PathsThe boot, sump and pipework actually become one solid structure, creating a 100% watertight system, free of mechanical seals and potential leak paths. |

| Polyethylene ConnectionsEntry boots directly weld to polyethylene sumps using the electrofusion welding process to create one, soid structure. |

| Fiberglass ConnectionsA polyethylene sleeve is over-molded onto a metallic ring that is fiberglassed to the sump to create a watertight joint. |

GEMINI™ SECONDARY CONTAINED FITTINGS

Patented UPP® Gemini Secondary Containment fittings feature a two-piece design that can be fully welded and tested before closing the secondary, something no other brand can offer.

| Less Fittings, More SavingsDesigned to enclose standard one-piece primary fittings, thus drastically reducing the number of necessary parts, welds, time and overall cost. |

| Weld, Then TestAvoid discovering a breach in the system after the secondary has been welded, saving significant installation time and cost. |

| Complete ConfidenceWith Gemini’s integrity testing capabilities, you get a level of confidence which installers and end users have yet to experience until now. |

A VERSATILE PIPEWORK SOLUTION

UPP® pipework provides a non-corrosive alternative to steel & fiberglass with additional installation and performance benefits.

Greater Flexiblity

UPP® pipework is highly flexible unlike steel and fiberglass – it’s also structurally resistant to seismic activity, backfill, and traffic during install.

Non-Corrosive

Corrosion in steel piping can be caused by aggressive soils and can lead to large scale issues and joint failures – UPP® pipe and fittings simply cannot corrode.

Low Maintenance

With steel, ground movement, water hammer and friction losses can create ongoing maintenance costs after installation is complete, costs you can avoid with UPP®.

UPP® UL-971 Standard Primary Pipe

- Pipe outer layer: High Density Polyethylene (HDPE) grade PE100

- Pipe liner layer: Ethylene vinyl alcohol (EVOH) resin liner

- Pipe intermediate layer: Tie-layer which permanently bonds HDPE outer layer to EVOH resin liner layer

- Temperature rating: -22 °F to 122 °F

- Primary pipe pressure rating: 90 Psi

- Secondary pipe pressure rating: 50 Psi

- 1½” and 2” double wall pipe bend radius: 3’3″

- 3″ and 4″ double wall pipe bend radius: 13’2″

- 2″ single wall vent/vapor pipe bend radius: 3’3″

- 3″ single wall vent/vapor pipe bend radius: 9’10”

UPP® UL-971 Standard Fill Pipe Approvals

- UL-971 approved for fuels including:

- Motor vehicle fuels typically found in consumer dispensing facilities like gasoline or diesel including blended fuels with maximum 15% MTBE, 15% Methanol or 30% Ethanol.

- Concentrated fuels such as alternate un-blended fuels containing up to 100% concentrations of Toluene, Methanol or Ethanol.

- High blend fuels with higher than normal gasoline blends with maximum 50% Methanol or 50% Ethanol.

- Aviation and marine specialty fuels containing up to 100% kerosene or leaded gasoline.

- Biodiesel compatibility:

- Biodiesel up to 5% (B5)

- Biodiesel up to 20% (B20)

- Biodiesel at 97% – 100% (B99 / B100)

- All ASTM defined biofuel blends

- Michigan, Wisconsin, and Florida EQ-816.

UPP® EN14125:2013 Standard Primary Pipe

- Material: PE100 with EVOH resin barrier

- Primary pressure rating (bar/psi): 10/145

- Primary colour: Black with two clusters of four green stripes, clear inner liner

- Temperature rating: Class T1 Rating (EN14125) -40 °C to 50 °C

- Primary vacuum rating (-bar/”Hg): -0.9/-26.6

UPP® EN14125:2013 Standard Fill Pipe

- Material: PE100 with EVOH resin barrier

- Primary pressure rating (bar/psi): 6/87

- Primary colour: Black with two clusters of four green stripes, clear inner liner

- Temperature rating: Class T1 Rating (EN14125) -40 °C to 50 °C

UPP® EN14125:2013 Standard Coaxial (Secondary) Pipe

- Material: PE100 with EVOH resin barrier

- Primary pressure rating (bar/psi): 10/145

- Primary colour: Black with two clusters of four green stripes, clear inner liner

- Secondary colour: Black with six green stripes

- Secondary pressure rating (bar/psi): 5/72

- Temperature rating: Class T1 Rating (EN14125) -40 °C to 50 °C

- Primary vacuum rating (-bar/”Hg): -0.9/-26.6

- Secondary vacuum rating (-bar/”Hg): -0.6/-17.8

UPP® EN14125:2013 Standard Secondary Sleeve

- Material: PE100

- Secondary pressure rating (bar/psi): 5/72

- Primary colour: Black with six green stripes

- Temperature rating: Class T1 Rating (EN14125) -40 °C to 50 °C

- Secondary vacuum rating (-bar/”Hg): -0.6/-17.8

REAL CONTRACTORS, REAL REACTIONS

SEE HOW IT WORKS

From cleaning and prepping the components, to executing the weld, the simple 8-step electrofusion welding process yields watertight connections throughout the pipework system.